A number of important factors need to be considered when designing thermoelectric based assemblies. Often times, insufficient consideration is given to seemingly smaller aspects of the design and as a result the cooling performance is lower than expected. It is important to recognize that thermoelectric modules are basically heat pumps, although they are very responsive and controllable as well as fully reversible. When a voltage is applied to the TEC module circuit, heat is rapidly transported across the module thickness and must be removed effectively on the hot side to avoid overheating and permanent damage. Good heat sinking is necessary in any thermoelectric based assembly.

In a well designed system, the temperature difference across the thermoelectric module is maintained small and the device is operated in a favorable voltage range. These conditions increase the coefficient of performance of the assembly and reduce the amount of waste in to the heat sink. In an improperly designed system, the developed temperature difference across the TEC module circuit can be large, increasing the electrical power required and the amount joule heat generated and thereby reducing the cooling efficiency. Considering that the heat rejected from the hot side is the sum of the input electrical power and heat absorbed from the cold side, it‘s magnitude can be quite sizable. Thus proper selection of operating parameters based on the system design is important. Also, an effective hot-side heat sink (air or liquid based) is needed to satisfactorily transfer the waste heat out to the environment.

Many thermoelectric assemblies greatly sacrifice performance through the use of lower cost, inadequate heat sink types and poorly designed fan air distribution. For example, an extra 10-15°C rise at the TEC surface (as a result of higher heat sinking resistance) can significantly degrade the module and overall system performance. For most applications involving air cooling, higher fin density type heat sinks with low thermal resistance levels (when coupled with the proper fan) are required to achieve good performance.

The choice of fan and how it is configured with the heat sink is also important. Axial type fans are generally a good choice for fin or pin type heat sinks and can be be easily configured with the heat sink (using a shroud for proper standoff) to provide good airflow. Fan performance from one manufacturer to another, however, can vary considerably, so it is important to review the fan curves for both air flow and pressure capabilities. A difference of a few units in pressure drop can significantly impact the resultant air flow and therefore the net heat sink response.

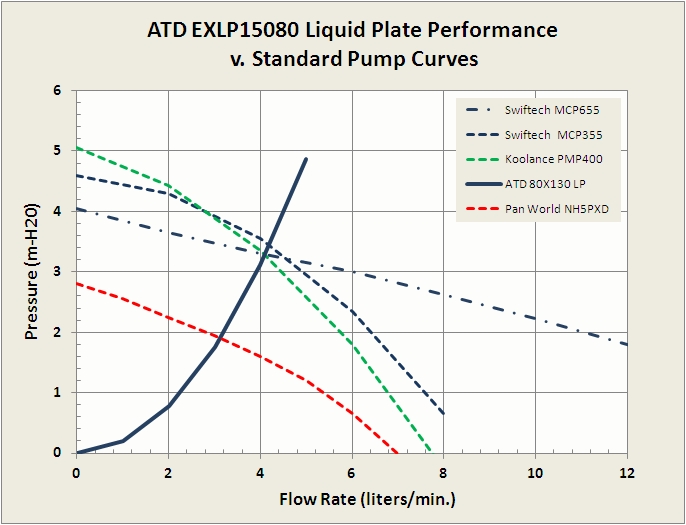

Liquid plates can also be used to effectively heat sink the thermoelectric circuit. They are commonly used also in air-liquid assemblies to control the temperature of a re-circulating fluid. Liquid plates are generally very effective heat sinks for thermoelectric assemblies often with thermal resistance levels significantly lower than comparable air-based heat sinks. This advantage is achieved largely due to the advantages of water as the coolant media with its good heat transfer properties and higher heat capacity. However, the extra complication and costs of pumps, tubing, reservoirs and radiators needs to be considered before implementing liquid plates for heat sinking. The performance of commercially available plates also varies considerably based on the differences in design and construction. They should be reviewed carefully in terms of fluid flow (or pump) requirements to achieve the stated performance numbers.

Since thermoelectric modules (TEC’s) are at the core of these assemblies it is important to understand how best to handle them. TECs are composite structures consisting of relatively delicate thermoelectric (semiconductor) elements bonded (soldered) between two stiff and brittle ceramic substrates. TEC modules tend to exhibit good strength in compression, but are somewhat weak under shear or tensile loading. Good assembly practice clamps the modules in compression and isolates the module circuit from other types of loading. Excessive vibrations and thermal cycling should be minimized to prolong module life. With proper design techniques, MTBF for thermoelectric based assemblies can exceed 100,000 hours.