Guidelines

A wide range of pump sizes and types are commercially available. For water based chillers, like our air-to-liquid or liquid-to-liquid subassemblies, it is important to choose a suitable pump to ensure a good overall system response. The resultant pump flow rate will influence the performance of the chiller and it depends on the physical characteristics of the complete fluid circuit. These physical characteristics include a combination of friction losses based on the diameter and length of tubing, flow resistance through the chiller, elevation differences within the system and other losses incurred by other components in the flow path. To identify a suitable pump from a manufacturer, you generally need to first know the desired flow rate and have a good estimation of the required total heat (= static + friction head). Having extra margin in pump head rating is usually desirable. Manufacturers generally provide the above ratings on their pumps including pump curves.

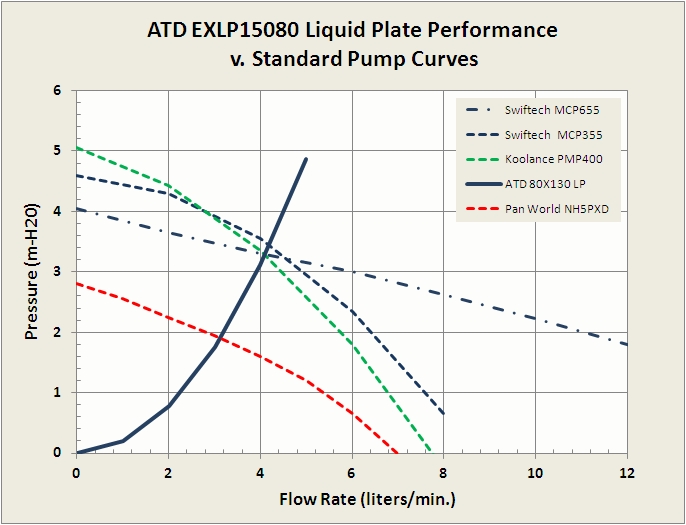

Magnetic centrifugal type pumps are commonly used with thermoelectric chiller systems, although other pump types can be employed. Manufacturers publish pump characteristic curves that show the relationship between discharge pressure (total head) versus flow rate at a specific operating pump speed. This pump curve can then be correlated with the system (loss) curve to identify an operating point and whether the selected pump is suitable for your application. Commonly, these two curves are graphically superimposed to identify this pump operating point which is at the intersection of the curves. This pump operating point can also be compared against the BEP (Best Efficiency Point) rating by the manufacturer to determine if the pump will operate efficiently. Other factors to consider include efficiency of the pump since excess heat degrades chiller performance, rated pump life, material compatibility with the fluid being pumped.

The Figure below shows the response of our 150mm x 80mm liquid plate (plus a few meters of 8mm tubing) versus some commonly available pumps. (Generally a complete fluid system would have other components and losses to consider in addition.)