Successful Thermoelectric designs require a complex combination of mechanical, electronic, heat transfer and fluid flow technologies. Here’s a selection of topics to help you navigate to your goal.

Theory

- How Do Thermoelectric Systems Work?

- The Peltier/Seebeck Effects

- Development of Thermoelectric Modules

System Design Considerations I

- General

- Heat Sinks/Fans

- Liquid Plate

- Thermoelectric Modules

- Powering TE Circuits

System Design Considerations II

- Interfaces

- Liquid Based Assemblies

- Thermal Resistance

- Advantages/Applications

Guidelines for Constructing Assemblies

Operating Assemblies and Performance Curves

Some Practical Thermal Management Examples

How Do Thermoelectric Systems Work? Thermoelectric modules or coolers (TEC’s) are compact, solid state heat pumps. Structurally, they consist of an array of N and P type semiconductor couples sandwiched between rigid ceramic substrates. A single couple consists of a pair of N and P type elements wired in series. Modules generally possess a large number of couples in series. When a voltage is applied across the module circuit, current flows proportional to the element size and number of couples. Electrons in the N type material and electron holes in the P type material transport heat from one surface (absorption side) of the couple to the other surface (rejection side). The couples within a module are arranged such that all the couples behave thermally in parallel which enables useful amounts of heat to be transported from one substrate to the other. Heat, which is actively transported across the thermoelectric module, causes one substrate surface to cool while the other becomes hotter. As a result, all thermoelectric systems require effective heat sinking on the hot (heat rejection) side of the thermoelectric module circuit. The better the heat sink performance, the greater the resultant performance of the thermoelectric modules and the overall system. Inadequate heat sinking will cause the hot side (of the module) temperature to rise as well as the temperature differential (DT) across the module degrading overall assembly performance. Severe temperature rise can potentially damage the thermoelectric modules. High capacity heat sinks with optimal fin density, thick base for heat spreading with good, uniform air flow through the fins will enhance the performance of most thermoelectric assemblies. Liquid plates are also a good choice for heat sinking, but are generally more expensive to implement due to all the ancillary components required. The magnitude of heat that can be handled by a chiller assembly (i.e., heat sinks, fans, modules) depends on a number of factors including the number and types of modules employed in the circuit, the thermal resistance of the heat sinks employed, the ambient operating temperature and the voltage applied. Other factors include the fan or pump performance, resistance of the interfacial layer, the quality of the DC power delivery to the TEC circuit and possibly a few other minor effects. With proper system design and operation, effective cooling performance can be achieved. The amount of cooling as well as specific process temperatures can be easily and precisely controlled by regulating the applied DC voltage to the thermoelectric circuit. Closed-loop feedback control (with sensors) is generally a good method for controlling the thermoelectric-based chiller response. The sensors measure air, fluid or solid temperature, which is used by the controller. PWM (pulsed width modulation) type controllers are commonly used since they work well with DC power. The Peltier/Seebeck Effects The development of thermoelectric modules was based on discovery of the Peltier Effect. This effect, first discovered in the early 19th century by watchmaker, Jean Peltier*, demonstrated that heat could be absorbed at the junction between dissimilar metals in intimate contact under an applied voltage. The Seebeck Effect is a related but inverse effect, i.e., a potential is developed when two dissimilar metals, placed in contact, are subjected to heat. Temperature readings from thermocouples use the voltage generated by the Seebeck Effect. In the early 20th century Russian investigators began exploring methods to commercialize the Peltier Effect. They discovered that the cooling effect could be significantly amplified by employing specific material combinations. Later investigators found that semiconductor materials in particular exhibited a pronounced Seebeck/Peltier effect. Semiconductor-based modules were purposely doped with both N and P type chemistries in order to build practical thermoelectric devices. Using both N and P type chemistries allowed heat to flow in one direction (all in parallel) while the current flowed in series in a single electrical circuit. Production methods were eventually developed to produce these materials in pellet like form so that multiple pairs (or “couples”) could be easily and densely packed and soldered to create a relatively large cooling response within a single small footprint device. * a more in depth discussion on this subject can be found elsewhere Development of Thermoelectric Modules The research thrust in thermoelectrics over the past 50 years has been largely to improve performance and efficiency of modules through optimized chemistries and improved manufacturing methods. The most commonly used semiconductor chemistries for cooling type modules include compounds based on bismuth, tellurium and antimony. R&D efforts continue in an attempt to achieve cooling performance similar to conventional CFC based refrigeration systems used in larger scale cooling systems. Recent efforts in thin film, semiconductor designs appear to have made significant gains, but only a limited number of commercially viable products are available and they tend to be expensive and targeted towards very compact cooling applications. A small fraction of the commercial thermoelectric market is aimed at electrical power generation applications, commercializing on the Seebeck Effect (instead of the Peltier Effect). Relatively large Seebeck coefficients can be generated using standard thermoelectric modules constructed with a high number of couples can generate appreciable voltages with higher temperature differentials. The energy conversion efficiency, however, is typically relatively low, generally less than 5%, which renders this technology somewhat unattractive except where other options are not practical. Significant research efforts have been focused on improving this performance, especially for waste heat recovery purposes.

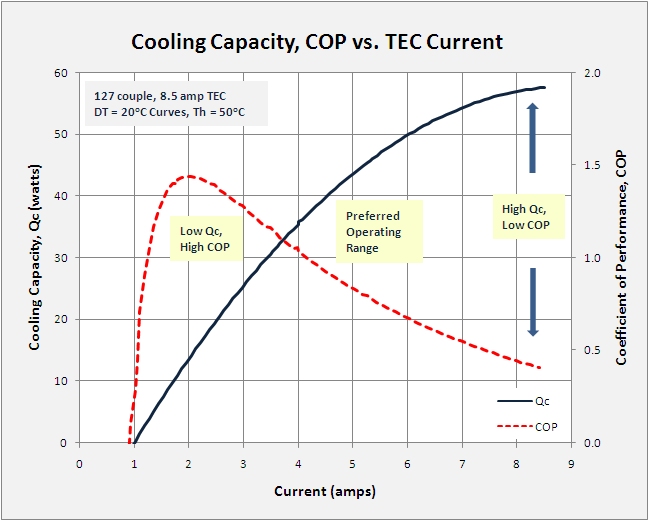

General A number of important factors need to be considered when designing thermoelectric based assemblies. Often times, insufficient consideration is given to seemingly smaller aspects of the design and as a result the cooling performance is lower than expected. It is important to recognize that thermoelectric modules are basically heat pumps, although they are very responsive and controllable as well as fully reversible. When a voltage is applied to the TEC module circuit, heat is rapidly transported across the module thickness. The TEC cooling response (Qc) is however nonlinear with applied voltage. What this means is that just increasing the voltage does not necessarily result in a proportional increase in Qc . This is also reflected in the COP (Coefficient of Performance = Qc/IV) curves which largely show decreases in COP as voltage and temperature differential across the TECs increase. In a well designed system, the temperature difference across the module circuit is small and the device is operated within a favorable voltage range. Conversely, in an improperly designed system, the temperature difference across the TEC generally becomes large and much of the electrical input power is converted into joule heat rather than useful cooling power. Considering that the heat rejected from the hot side is the sum of the input electrical power and heat absorbed from the cold side (Qh = Qc + IV), it‘s magnitude can become quite sizable. Thus proper selection of operating parameters based on the system design is important. Also a very effective hot side heat sink system (heat sink, fan and shroud) is important to satisfactorily move the heat away from the module surface to the environment. Many commercially available thermoelectric subassemblies greatly sacrifice performance through the use of lower cost, inadequate heat sink types with poorly designed fan air distribution. For example, with 200 watts of Qh heat from the TE modules an increase of 0.05 to 0.075 C/W in heat sink resistance will cause an extra 10-15°C rise at the TE surfaces. This added temperature rise will significantly decrease cooling capacity and performance of the subassembly. Heat Sinks/Fans Many thermoelectric designs employ air-based heat sinks to rid heat from the hot side of the subassembly or on the cold side to remove heat from a closed environment. The assembly performance is, therefore strongly dependent on the effectiveness of the air-based heat sinking. The hot side temperature rise (on the thermoelectric circuit) influences the the cooling capacity (Qc) of the assembly, i.e., a higher temperature differential (Th-Tc) reduces cooling capacity. As an example, if a thermoelectric module rejects 100 watts on the hot side (Qh), an increase in heat sink (plus interface) thermal resistance from 0.1 C/W to 0.2 C/W (which would be typical for heat sinks) would increase the temperature at the module surface above ambient from 10oC to 20oC. The extra 10oC rise would have a pronounced reduction in cooling capacity (e.g., for a 127/8.5 module, Ta=35C, Tc = 25C Vin =12V, the reduction in cooling capacity Qc would be >20%). For most thermoelectric applications, higher fin density type heat sinks with low thermal resistance levels (when coupled with the proper fan) are required to achieve good performance. Often times, bonded-fin type heat sinks are required to handle the large heat being expelled by a TE module circuit. Extrusion technology has improved to the point where high density (HD) fin design heat sinks can now be produced by some suppliers with similar configurations to bonded fin heat sinks. They also offer some advantages over bonded fin heat sinks, most notably the absence of the glued fin joint. An alternative approach (to reduce the stringent heat sinking requirement) is to operate the thermoelectric modules in a region of high COP, so that the waste heat (Qh) is significantly reduced. This approach, however, requires more modules to be used to generate the same level of cooling and also, usually means that the heat sinks need to generally be physically larger to accommodate the extra modules. The choice of fan and how it is coupled and configured with the heat sink is also another critical aspect. Axial fans tend to provide the most airflow per watt of electrical energy consumption but their characteristics mean that the net airflow is sensitive to even the smallest resistance. Fan performance from one manufacturer to another can vary considerably, so it is important to review the fan curves for both air flow and pressure capabilities. A difference of a few units in pressure drop can significantly impact the resultant air flow and therefore the net heat sinking response. Additionally, in many designs the flow patterns are often non-optimal, leading to inefficient use of the cooling air. Therefore the right choice of fan model, coupled with good air duct design and fan location is crucial to achieving satisfactory heat sinking performance. Liquid Plates Liquid plates are generally used to remove heat and control the temperature of a recirculating fluid. They can also serve as very effective heat sinks for thermoelectric assemblies often with thermal resistance levels significantly lower than comparable air-based heat sinks. This advantage is achieved largely due to the advantages of water as the coolant media (high film coefficient) and its higher heat capacity. However, the extra complication and costs of pumps, reservoirs, radiators needs to be considered before implementing liquid plates for heat sinking purposes. The performance of commercially available plates varies considerably based on the differences in design and construction. Copper-tubed plates and gun-drilled plates have simple designs which can be useful in some applications, but generally exhibit relatively higher thermal resistance levels due to their limited internal surface area for heat transfer and relatively low Reynolds numbers (Re). Low Reynolds numbers result in low coefficients of heat transfer and therefore low performance. Since the Re number is directly related to velocity, tube in plate designs rely on high fluid velocity to push the Re level up. However, high velocity means high flowrate which creates two additional problems; a high enough flowrate is often not achievable by most pumps resulting in a less than expected flow rate (due to pressure drop issues). Generally centrifugal pumps are used, but with these flow restricting liquid plate designs the full flow rate is not realized since they are head limited (especially since head pressure increases as the square of flow). Simply reducing the bore of the tube to speed up the flow is not an option since that results in less wetted area. Sometimes Internal flow disrupters are used in an attempt to mix or “turbulate ” the flow but the gains are often marginal since in order to work, the boundary layer close to the channel wall must be disrupted, not the core flow. Therefore, in order to overcome the shortcomings of “tube in plate” designs, an array of small channels in series, with high velocity and large wetted area is generally the better course. This is the approach adopted in the best performing liquid plates. By careful balancing of channel geometry with hydraulic resistance, low overall thermal resistances are achieved without incurring crippling pressure drop. These types of designs are generally produced by machining and/or brazing, or in our design, by precision extrusion. Thermoelectric Modules Thermoelectric modules are commercially available in a wide range of sizes and internal configurations. For chiller applications, modules with higher cooling capacity ratings are commonly used , e.g., 127 couple, 8.5 amp or higher amperage types. The 127 couple module enables operation at convenient 12 VDC per module, but also can operate at slightly higher voltage for more cooling output or lower voltage for improved COP (coefficient of performance). The larger 40mm x 40mm footprint of these modules also helps spread the heat (on the heat sink) for improved dissipation. Most thermoelectric modules, from the various manufacturers, often times look physically similar, however the internal construction can vary significantly. Differences in the chemistry of the thermoelectric elements and the construction practices to manufacture the modules can influence both the performance and long term reliability. Differences in thermoelectric element chemistry can influence the maximum cooling capacities, maximum achievable temperature differentials as well as the voltage-current relationship. More reliable modules typically employ diffusion barriers between the thermoelectric element surfaces and the substrate conductor pads to prevent internal, cross diffusion which can slowly degrade module performance. The manner in which this diffusion barrier is applied (and adhered to the elements) can also influence the life of the module, poor adherence eventually increases internal module resistance (temperature cycling can hasten this effect). Generally higher temperature internal solders that bond the thermoelectric elements to the substrate result in more reliable module performance. Many less expensive thermoelectric modules use low temperature solder which can yield satisfactory performance in simple steady-state applications, but can degrade progressively over time from normal operation. Powering TE Circuits Thermoelectric modules (TECs) can be powered over a wide range of voltages from 0 VDC to the maximum rated voltage (Vmax) for a specific module or circuit of modules. In addition, with their reversible nature the TEC circuit can be controlled from – Vmax through +Vmax which is a unique capability for cooling devices. This capability allows TE based assemblies to be operated at a fixed voltage for steady cooling or controlled in a variable manner through regulation of DC voltage delivery. The maximum rated voltage for a TEC is proportional to the number of internal semiconductor couples and is generally specified by the manufacturer. For example, a 127 couple module will typically have a voltage range of approx. 0 volts through ~ 15 volts (max.) at 25oC and a 71 couple module has a range of 0 volts to ~ 8.5 volts. The voltage-current relationship also varies with the average temperature of the module. Most manufactures specify a fixed amperage range for a module, e.g., 0 – 8.5 amps for a 127couple, 8.5 amp TEC, so the voltage range or maximum voltage will vary with temperature. As mentioned previously, the TECs can be operated from the min. to max. voltage levels, but operating near either extreme is generally not desirable. Operating near the maximum voltage rating will yield the highest cooling capacity and the largest temperature differential, but also sacrifices performance efficiency (generating the highest amount of waste heat) and tends to thermally stress the TEC. Even though the TEC performance curves show the greatest cooling capacity (Qc) at Vmax, in practice, the high level of waste heat (Qh) increases the hot side temperature of the TEC creating a greater temperature differential (DT). The greater the DT level, the less the actual cooling capacity. The coefficient of performance (COP) = Qc/IV is another important consideration when powering TEC circuits. Operating the thermoelectric based assembly in a high coefficient of performance (COP) regime can provide significant performance advantages, but requires careful design to ensure cooling objectives are achieved. Operating in a high COP regime reduces the power requirement (Pin = IV) for a unit of cooling (Qc). As a result, the waste heat (Qh) is reduced since Qh = Qc+IV and the rejection (hot) side heat sink stays cooler and the hot side temperature (Th) of the TEC is reduced (which also reduces the module temperature differential DT). Another benefit is that the thermal stresses on the TECs are reduced helping prolong module life. The primary disadvantage of this approach is that more modules may be required in the assembly design to achieve a specific level of cooling (Qc) required. This cost penalty, however, is usually more than offset by reduced long term operating costs and improved reliability.

Interfaces The interface layer between the thermoelectric module and the heat sink can have a strong influence on the overall system response. This layer needs to be uniform, compliant and thermally conductive to ensure good heat transfer between components. In the absence of a conductive interface layer, the impedance would be high since an air gap would exist. Reducing this gap thickness is also important. The mating surfaces between the module and the heat sinks (or plates) need to be flat (1uin/in or better) and smooth (e.g., 63 finish from milling) to minimize the interfacial layer thickness. Even the best interface materials possess thermal conductivity values significantly lower then the heat sink material, so the thinner the better. The TE module ceramic surfaces are typically very smooth and flat since they are lapped. Most of the attention should be focused on the heat sink surface. For multi-module circuits, height variations can impact the interface thickness, so tight module height tolerance is beneficial. For our assemblies, we measure, sort and match module heights to ensure that a thin gap results. Thermal grease (or compound) is a good choice for thermoelectric assemblies based on its semi-fluid nature and ability to fill gaps and surface imperfections. Entrained air voids and non-uniform coverage within the interface layer can reduce assembly performance. Liquid-Based Assemblies Liquid cooling can provide performance advantages over air-based systems, but does add complexities and potentially higher costs. Liquid plates generally exhibit low thermal resistances, often significantly lower than similar sized air-based heat sinks. A well designed liquid plate also offers low fluid flow resistance so that moderate pumping capacities are sufficient. The typical liquid cooling (or heating) circuit includes a number of key components, including a liquid plate, possibly a heat sink and fan, (for air-to-liquid (A-L) or liquid-to-liquid (L-L) designs), radiator (for L-L designs), pump, expansion reservoir and connective piping. Pumps should be selected that provide sufficient flow and pressure capabilities to overcome the flow losses, enable good chiller performance and also satisfy flow requirements for the end application. All components in the system should be carefully selected and designed to limit flow disruptions and enhance performance. Water or a modified water composition are generally the coolant of choice for liquid-based systems based on their low cost and effective thermal properties. The disadvantages of pure water are potential corrosion concerns and the risk of freezing for low temperature applications. Chemical modifications to water can help reduce these concerns. Commonly available additives can be used to minimize corrosion and bio-fouling and glycol antifreeze used to reduce the freezing risk. Additives are particularly recommended for systems that sit idle for prolonged periods. Flushing the system periodically can also extend component life and reduce corrosion effects. Our liquid plate design allows disassembly for easy access to the internal channels for cleaning. Air entrapment is a concern for any liquid based cooling system due to the potential impact on performance. Steps can be taken during assembly and fill of the coolant to remove air. Generally lowering and rotating the components 90o repeatedly while filling, especially the liquid plate, will allow most air bubbles to escape. Thermal Resistance The total thermal resistance in a chiller assembly consists of the sum of each of the individual resistances along the heat transfer paths. For a thermoelectric based assembly this includes both the hot and cold paths on either side of the module(s). For an air based assembly the individual resistance elements from the TEC include: the interface, base plate to fin junction, fin base to fin tip and fin surface to air. Additionally, the spreading resistances across the base of the heat sink can have a strong influence on the heat sink resistance, since the TEC heat flux is concentrated along the module substrate area which is smaller than the heat sink base area. Typically the fin to air interface is the most significant resistance so maximizing heat transfer at the fin surface boundary layer will enhance performance. So, careful design consideration of the complete heat sinking subsystem is important to ensure optimal air flow. The heat sink base thickness, fin width, height and spacing as well as the distribution and velocity of fan air needs to be considered. Fan performance characteristics and location about the heat sink can be critical. For example, a fan placed directly on the fin tops may only effectively cool a fraction of fins and the flow front may not develop properly to extract the maximum heat. The net heat sink resistance will ultimately determine the module hot side temperature (Th), the cold side temperature (Tc), the potential cooling that can be achieved by the TE module circuit and thus the overall assembly performance. Similarly in liquid based systems, the internal design of the liquid plate and how the coolant is forced through the liquid plate channels influences the overall thermal resistance. Designs with high internal surface area, high film coefficient of heat transfer and optimal channels generally results in good thermal resistance characteristics for thermoelectric based exchangers. *The thermal resistance is expressed as delta-T (temperature between the heat sink and air) required to dissipate a given amount of heat. At ATD we specifically define the delta-T as Tbase-Tambient. note – slightly different definitions may be used by other manufacturers. Advantages of Thermoelectric Designs for Cooling and Temperature Control Some Specific Applications The compact and modular nature, precise temperature control capability, combined heating and cooling capability and the high reliability of thermoelectric modules enables a wide range of design options. Some common applications include:

Assembly Guidelines The following guidelines are intended to help users design and build thermoelectric-based assemblies. Since thermoelectric modules (TEC’s) are at the core of these assemblies it is first important to understand how best to work with them. TECs are composite structures consisting of relatively delicate thermoelectric (semiconductor) elements soldered between two stiff and brittle ceramic substrates. TEC modules tend to exhibit good strength in compression, but are somewhat weak under shear or tensile loading. Good design and assembly practice clamps the modules in compression and isolates the module circuit from other types of loading. A uniform distribution of fasteners (generally around the perimeter of the heat sinks) with proper tightening procedures and torque levels will ensure uniform compression on the TECs. Mating surfaces (from the heat sink, liquid plate or surface plate) need to be flat and smooth and interface materials are necessary to thermally bridge the surfaces. Spring washers should be used to maintain fastener tension and help accommodate any changes due to thermal expansion during operation. Belleville or wave washers are a good choice for this purpose. All mating surfaces should be thoroughly cleaned and degreased prior to assembly. A very thin and uniform layer of thermal grease is applied and the TEC is then positioned against the mating heat sink or similar surface. The TEC should be gently translated back and forth to help fill the gap, surface asperities and displace excess grease. The process is repeated with the opposite TEC and mating surfaces. With the TEC circuit assembled between the mating component surfaces, it is important that the fasteners be tightened sequentially and evenly to ensure uniform compression. (Uneven tightening of the fasteners across the array of fasteners can potentially crack the ceramic substrates or damage the internal elements.) Generally it is recommended that the fasteners be tightened with just enough torque to bring the opposing faces in contact under light compression. Then tighten the fasteners in a cross sequencing pattern while increasing the compression incrementally to the TECs. Tighten the array in ~25% increments (of maximum torque) until the maximum torque is achieved. Re-check torque after a few hours (minimum), since the excess grease can extrude over time causing the fasteners to loosen slightly. The proper torque (for the TEC circuit) can be calculated using the following relationship: T= (P * A * K * D)/N T = Applied fastener torque (in-lbs), P = Pressure/TEC (normally 75-100 psi), A= Total substrate area of TEC’s (sq in), N = number of fasteners, K= torque coefficient (typically 0.15 for steel fasteners, Ref: Machine Handbook), D= nominal bolt diameter (inches)

Power Supply and Control Guidelines Most thermoelectric assemblies operate on low voltage, DC power. Smooth power delivery is preferred but not essential. An AC ripple component less than 10% is generally recommended to avoid performance losses (based on TE manufacturer recommendations). Switching type power supplies are a suitable choice, since they usually exhibit small ripple components, are compact, lightweight and reasonably priced per watt of power. Switching power supplies can also pair well with the typical PWM controllers used to regulate TEC applications. Several power delivery approaches can be used with TE module circuits and it is really a matter of application need or preference. Where only bulk cooling is required and under-cooling is not a concern, TEC’s can be operated directly off a fixed voltage power supply. It is important, however, to ensure that the proper fixed voltage is selected for the TEC circuit employed and with adequate amperage margin. Often times during start up, the amperage draw is greater than at steady state. Also, cooling performance can drift with this mode of operation, if ambient conditions vary widely. PWM-type temperature controllers are commonly used to control thermoelectric chillers. These controllers are attractive since their Mosfet-based design allows the DC voltage to be precisely controlled and with temperature control circuitry can deliver power smoothly. Many PWM controllers can provide feedback proportional control, provide bi-directional temperature control and are capable of providing set point stability within +/- 0.1oC using an appropriate temperature sensor. Operating Assemblies and Performance Curves Thermoelectric modules can be operated over a relatively wide range of voltages, from 0 volts to the maximum rated voltage (V-max) for that particular module. The V-max rating depends on the number of internal couples and the operating conditions, i.e., hot side and average temperatures. So, specific module types can be selected to yield desired cooling and specific operating parameters. Choosing an operating voltage for a particular TEC or TEC circuit generally involves some trade offs. Operating near V-max can (on paper) provide a high cooling capacity (Qc) and high overall temperature differential (DT = Th -Tc) but results in a low COP (coefficient of performance = cooling capacity/power in). The lower COP increases the power requirement (Pin) which also results in higher rejected heat (Qh = Qc+Pin) from the module to the heat sink. The higher Qh either elevates the hot side module temperature (Th) or necessitates a larger more powerful heat sink to maintain a lower temperature. If a higher Th temperature results , the DT across the module increases and the cooling capacity (Qc) is diminished. Conversely, operating at the lower end of the voltage (Vin) range of a specific TEC can yield very high COP levels which can be attractive, but the cooling capacity and maximum temperature differential can be very limited in this operating regime. The figure below illustrates various operating conditions superimposed over a set of cooling capacity curves. Operating at a higher COP level can help reduce the heat sink requirement as well as the DC power requirement. However, the trade off is that more TEC capacity (i.e., larger modules or more modules) may be required to achieve the desired cooling capacity. The reduced operating costs over time, however, may make up for any additional upfront component costs. For most applications, it is generally beneficial to select the operating range which yields a good balance between COP and cooling capacity (Qc).

Some Practical Thermal Management Examples Illustrating considerations in choosing and sizing thermoelectric systems Below are some practical examples of various thermoelectric assembly types and how to approach developing a design for cooling, heating or precise temperature control. Example Listing: Example 1: An electronics cabinet containing heat generating components that must be kept below 20oC. The external air temperature varies between 20oC in winter and 30oC in summer. Example 2: A post-operative surgical wrap uses pumped cooled and heated water to help rehabilitate a knee after surgery. The schedule involves cooling the knee to 5C for 15 minutes and then heating the knee at 30C for 15 minutes. The external air temperature varies between 20oC in winter and 30oC in summer. Example 3: A fermentation process that generates no internal heat but must be maintained at 31oC +/- 0.5oC with an external air temp that fluctuates over the range 10oC – 30oC within any given 24 hr cycle. Example 4: The air in a closed volume of approximately 1 cu m is required to be dried from a humidity level of 60% down to 20%. The initial air temp in the volume is 25oC. The final air temp desired in the volume is also 25oC. Example 5: A boat in storage requires that humidity in the internal cabin be maintained at 30% RH max. to prevent corrosion and mold damage. The boat sits outside and the temperature can fluctuate from 0oC in winter to 30oC in summer. Example 6: An isothermal surface is required for examining biological samples. The set-point temperatures need to be precise (within +/- 0.5oC) and over a small range of temperatures below freezing to +10oC above freezing. Example Descriptions: Example 1: Cooling an Electronics Cabinet In this example, an air-to-air chiller assembly is required to maintain 20oC air within an electronics cabinet. For this application, the heat load (Qc) is the sum of various internal electronic components which is assumed to be a constant 100 watts total. Now to size the subassembly, we design for the worst case ambient temperature, which is Ta = 30oC (of course this temperature could vary based on the application). So the thermoelectric circuit needs to pump the 100W of heat to maintain 20oC (the cabinet design temp.) at an external temperature of 30oC., so the air DT = 10oC. However, the heat sinks in the chiller assembly incur a thermal resistance so the temperature differential (DT) across the thermoelectric module will be greater than 10oC. If we know the resistance values we can estimate the heat rise on the hot side and drop on the cold side using performance curves for Qc and Qh. From a review of the performance curves for standard TECs, it can be determined what type of TECs are required to provide sufficient cooling (or heating). It is likely that two or three 127 couple, 8.8 amp modules will be required to remove the 100W with proper heat sinking. If a single standard unit cannot provide the required cooling then either multiple modular units can be employed or a custom design pursued. If the 20oC temperature is required to be accurately maintained (say, to avoid undercooling) then a feedback temperature controller should be used, and in this case only a simple single direction, “cooling only” type is needed. Example 2: Post-operative Surgical Wrap An effective chiller would use an adaptive feedback temperature controller with a temperature sensors located both in the supply and return water lines. This capability is beneficial to adjust or adapt for changes in the body response to avoid possible over or under cooling (or heating). The controller and sensors can simply monitor the fluid continuously and adjust the chiller response as needed. Use of a bi-directional controller and thermoelectric circuit allows the chiller to alternate cooling or heating as prescribed by the therapy schedule. These systems generally require accuracy and responsiveness to avoid sluggish change in water temperature which can be both time consuming and potentially deleterious to the patient. General sizing of this exchanger depends on the particular portion of the body to be regulated and the exact response required. Testing can aid in establishing the general range of thermal resistances in both heating and cooling modes. The amount of heat released by the knee is typically small, on the order of 10-20 watts, but greater cooling capacity will be required to change the volume of coolant within a reasonable amount of time to a setpoint temperature. The feedback controller will regulate the amount of cooling delivered so it is just important to ensure that sufficient cooling margin is available. Key components for this application generally include an air to liquid chiller, bi-directional temperature controller and sensors, DC power supply and pump to ensure uniform and sufficient water flow. Example 3: Fermentation Process This design generally requires that a non-steady state heat balance be performed on the fermentor, taking into account it’s heat loss or gain from the surrounding air by convection/conduction as well as it’s thermal inertia. Modeling can assist in these applications to help quantify the maximum Qh and Qc capacities, considering max DT and transient process effects, to enable quick convergence on an effective design. We have in-house models and can assist in some simulations for more complex designs, if required. Often times the modeling can save time, cost and aggravation in excessive design iterations in developing the proper solution for your application. Example 4: Closed System Humidity Control Fortunately, the heat rejected at the hot side is not wasted but recycled to re-heat the outgoing air. Note that re-heating the air will cause the relative humidity (RH) in the target environment to fall , i.e., it has a “drying” effect. Therefore, the higher the acceptable temperature in this environment, for a given RH, the more effective the TE based dehumidifier will be in collecting and removing additional moisture since it can then operate effectively at a higher cool side temperature (Tc). Suppose the cabinet contains 1 Kg of air (approx 1 cu m under normal conditions) and we want to go from state 1 (25C dry bulb, 60% RH, .012 kg water/kg air moisture content ) to state 2 which is 12.5C dry bulb, 20% RH and 0.0019 kgwater/kg air moisture content. The sensible heat load is (25-12.5)*1005* 1=12.5 kJ The latent heat load is (0.012-0.0019)*2376=24 kJ TOTAL=12.5+24=36.5 kJ If this process were specified to take place over one hr, it would require an average Qc of 36.5e3/3600=10Watts. However there is a further consideration in that the chiller must operate below the dewpoint to condense the moisture out of the air. The dewpoint at condition 1 is just over 19C and at condition 2 is about 4C . Therefore the chiller should have a average Qc of at least 10W over the range 19C to 4C. In practice it will have a higher Qc at 19C than at 4C so the rate of dehumidification will be rapid at first, gradually falling off as the temp declines . Example 5: Dry Boat Storage – Humidity Control Example 6: Isothermal Surface Plate As a possible example, a 150mmx150mm surface plate is needed to quality test small circuit boards in production at 15oC +/-1oC for roughly five minutes. The heat load is largely passive and small. A 150mmx150mmx12mm aluminum plate (or slightly larger) is produced with a milled outer surface (flat) and dark anodized surface for wear resistance. A 2×2 array of 40mm TEC’s is employed, each TEC is rated at 127 couples and an Imax rating of 6 amps. On the hot side (TEC’s), either a single large or two smaller air-based heat sinks with fans are used to remove the pumped heat. Alternatively a liquid plate could be used with coolant circulated to a radiator (this would yield a more compact and lower profile assembly design). A 24 VDC switching power is employed with a 250 watt capacity, the TEC circuit is then wired 2 in series x 2 parallel circuits so that each TEC receives a maximum of 12 volts. A PWM temperature controller is coupled with the power supply and thermal sensor (thermistor, thermocouple or RTD type) is embedded in a blind hole drilled to the center of the plate. The PWM controller allows the 15oC temperature to be maintained precisely or adjusted to maintain other set points. Other TEC based designs allow design flexibility so that either reduced amperage TECs (for more energy conservation) or higher power TECs could be employed. Additionally, multistage TECs could be employed (e.g., a 2-stage TEC) for deep cooling set points. We can assist in the sizing or design for these or other applications. Please call us to discuss.Theory

Design 1

Design 2

Assembly

Operating

Examples

When considering thermoelectric-based cooling for an application, the first question generally asked is “What is the magnitude of heat required to be handled by the chiller assembly?” (i.e., the cooling load (Qc) or heating load (Qh) in watts or similar units). The next consideration is usually the magnitude of the temperature differential (delta T or DT) under which the assembly has to operate. The cooling and heating capacities of thermoelectric assemblies are strongly dependent on temperature differential (DT) (as well as the average temperature). Under a high DT, Qc will be low and conversely when pumping heat through a low DT, the cooling capacity will be high. Qc versus DT (performance) curves for thermoelectric modules can help guide proper module selection and optimize operating parameters.

In this example, an air-to-liquid chiller is needed with adjustable temperature control capability for a biomedical application. This is an interesting case of heat transfer between a fluid filled membrane pad against human skin. It differs from typical heat transfer problems in that the thermal resistance between the cooling pad and the skin is complex since it involves heat transfer between the surface of the skin and subcutaneous blood capillaries which are responsible for transporting heat energy. Also, since the capillary behavior varies (i.e., dilate and contract in response to the body’s thermoregulatory system), the overall “thermal resistance” can vary over a very wide range so the chiller needs to be designed for worst case to be effective. The body’s system will detect the presence of a hot or cold skin area and act accordingly by adjusting the capillary blood flow. Hence a treatment, e.g., post operative heat therapy, which starts off by heating the knee may see an initial high rate of heat transfer diminishing temporarily as the capillaries react.

This example requires an air-to-liquid chiller with a custom designed liquid plate to integrate with the fermentor hardware, to maintain accurate temperature control (key to good product) and to avoid product contamination. Control for this application is a little more complex since the heat load can change from cooling (Qc) to heating (Qh) depending on the external ambient air temperature. The TEC circuit is easily reversible from heating to cooling simply by switching the polarity of the DC power. A good bi-directional temperature controller can handle this scheme and maintain precise set-points. Selection of the proper TEC type and number of TECs in the chiller circuit, i.e., proper capacity, is important to ensure that the necessary temperature range can be maintained. (Each TEC type has unique voltage, current and cooling/heating (Qc/Qh) characteristics and a review of performance curves helps selection.)

This example requires an air-to-air type chiller with custom, closed ducting on the process side to properly control the air flow and condition. In dehumidification applications, moisture is removed from air by lowering the air temperature to a level where water vapor condenses into liquid on a cold surface, collects and then is drained from the system. Dehumidification in thermoelectric chillers is promoted by ensuring that the cold side, heat sink temperature is maintained below the dewpoint as air is passed over the fin array. After shedding moisture the drier air is re-heated by subsequently passing through the hot side heat sink fins where it re-enters the target environment to absorb more moisture. As moisture condenses, it also releases latent heat (approx. 660 watt-hrs/liter of condensate) and this imposes an additional cooling load on the chiller since it must be “pumped away“ to the hot side, heat sink.

This application is best served with an air-to-air type cooler similar to the other dehumidification examples. In this application it is best to assume that the boat cabin or hull is not fully hermetically sealed and that ambient air can gradually infiltrate the internal volume. This means that the dryer has to work continuously in order to remove additional moisture carried in by the fresh air. In sizing this application, the first question (and probably the most difficult to answer is: how severe is the air infiltration rate? Short of measuring it (difficult), a reasonably good estimate can be made from HVAC data for buildings. Typically for loose fitting doors and windows, an infiltration rate of 5% of the boat’s volume per hour is a reasonable assumption. Suppose the boat cabin has an internal volume of 20 m3, this would yield an infiltration rate of 1 m3 /hr. The next question would be, what is the typical RH seasonal variation of the outside air? A quick look at local weather data should be provide typical conditions. Assuming worst case to be in the Summer and assuming Summer conditions (for this example) of 60% RH, 30oC by day, changing to 80%, 20oC by night the dehumidifier could then be sized using an analysis similar to Example 4 with an added infiltration rate of 1 m3 /hr.

This application involves uniform cooling of a solid, conductive plate (usually aluminum) using an array of thermoelectric modules. The outer surface of the plate is normally flat, but any machined detail is possible, such as a circular recess for Petri dishes. A single TEC can be used to cool a small surface plate but a symmetrical array of TEC’s would be required for larger surfaces or where greater cooling is required. The type of TEC’s selected can be sized based on knowing the mass of the surface plate, the heat load to be cooled and the time to cool objectives. On the hot or rejection side (of the TEC circuit) an air or liquid-based heat sink is required. To maintain precise set-point temperatures on the plate surface a feedback temperature controller with embedded sensor positioned within the plate generally works best. Isothermal plates for biological or other similar applications with only passive heat loads usually can operate with limited cooling capacity (and limited power input requirements). Again, however, a uniform array of TEC’s may be required to provide a uniform thermal profile especially during transient conditions. Applications with active heat loads can be similarly configured, but with higher power TECs and more effective heat sinking.