Our family of air-to-liquid chillers are very compact designs employing thermoelectric cooling technology to actively remove (or add) heat from a circulating fluid. All components used have been carefully selected or designed to yield strong product performance, high reliability and with attractive pricing. These chillers can be operated under a fixed voltage to simply bulk cool a fluid or can precisely control a fluid temperature through voltage regulation. Temperature control accuracies of +/- 0.1oC are possible with a closed-loop temperature controller.

Our family of air-to-liquid chillers are very compact designs employing thermoelectric cooling technology to actively remove (or add) heat from a circulating fluid. All components used have been carefully selected or designed to yield strong product performance, high reliability and with attractive pricing. These chillers can be operated under a fixed voltage to simply bulk cool a fluid or can precisely control a fluid temperature through voltage regulation. Temperature control accuracies of +/- 0.1oC are possible with a closed-loop temperature controller.

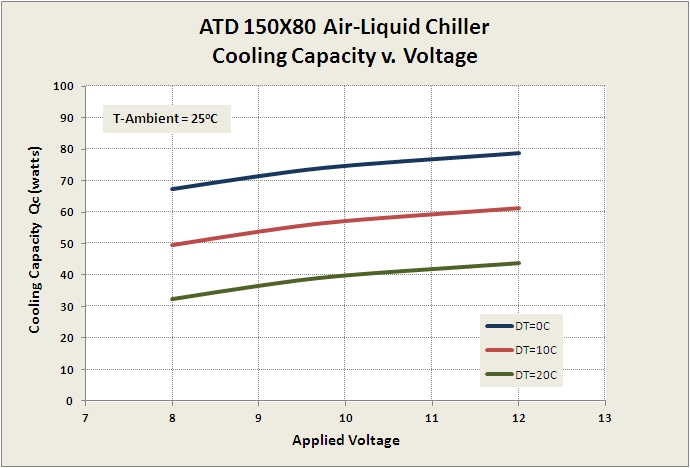

Our air-to-liquid chiller subassemblies operate on low voltage DC power and actively extract (or add) heat from a circulating fluid. This heat is moved or pumped from the liquid plate to an air-based heat sink (hot side) to expel the heat to the environment. These chillers can also be run in reverse to efficiently cool circulating air instead (heat is then passed to the fluid and generally expelled from a radiator in this case). These subassemblies are solid state, thermoelectric designs (no Freon), operating on safe, low voltage DC power and are highly reliable. Since heat is actively pumped through the thermoelectric circuit, temperatures significantly below ambient can be maintained (which is not possible with passive heat exchanger designs). The amount of heat transferred and the resultant fluid temperatures can be easily controlled by controlling the DC voltage supplied to the chiller. The cooling performance of our thermoelectric chillers offers advantages over Freon-based systems, including greater control flexibility, smoother temperature transitions and more precise temperature control. The primary components of our designs include a high-fin count extruded heat sink, a strong fan (higher flow and high pressure capable), low resistance liquid plates and sealed, higher temperature solid-state thermoelectric modules. Design Details Below are our standard air-liquid chillers: The hot side of the chiller consists of a high air flow 80mm fan and shroud oriented in impingement mode against our high fin density heat sink to ensure that waste heat is effectively removed with low thermal resistance. This performance ensures that the highest cooling capacities and efficiencies are achieved by the thermoelectric circuit by maintaining a lower hot side temperature (Th) and reduced overall temperature differential (DT). The liquid side of this chiller integrates our custom 150x80mm liquid plate which possesses a high internal wetted surface area with low overall fluid flow resistance. This extruded liquid plate design exhibits low thermal resistance and high heat transfer capacity which further enhances chiller performance. Our extruded liquid plate offers distinct performance advantages (e.g., low thermal resistance at low fluid flow rates) versus standard embedded copper tube designs commonly used in many liquid cooled chillers. The good performance at low flows eases the pump requirement which generally translates to lower cost, a more compact design and less added heat by the pump in to the process stream (i.e., therefore more net cooling power). The liquid plate consists of two endplates fastened to the centerbody. One endplate possesses two 1/8″ NPT machined passages; 8mm (5/16″) push-to-connect or 3/8″ barb tube fittings are standard for external connection. The fastened endplates allow easy removal for cleaning if required, i.e., to maintain consistent performance over time. All of our standard chillers employ high quality components for reliable, long life and high performance. With a feedback temperature controller and sensor, the chiller can provide precise control of the re-circulating fluid temperature. Alternatively, this design can be run in reverse mode by altering the voltage polarity to the thermoelectric circuit. In this mode, the low thermal resistance of the liquid plate acts as a very effective heat sink and the air circulating through the heat sink is chilled. In this operating mode, the liquid plate is usually coupled to a radiator to remove waste heat from the chiller. Our compact chiller subassemblies are specifically designed to be modular, allowing cooling capacity to be increased by simply linking multiple units on a common structural platform. For multiple designs, fluid connections can be provided for either series or parallel operation to meet specific flow requirements. The footprint of our standard single exchanger is 150mm x 80mm (5.9″x3.1”). It is rated at 79 watts of cooling (Qc) at Vin = 12 volts and T-ambient = 25oC (DT=0C). Besides operational flexibility and reliability advantages, the modular approach provides good performance per unit cost due to the lower cost of construction (v. a single larger heat sinks and liquid plates). For more detailed product information please see “Specifications” and “Drawings” for this product. Options – Various options are available for these products, including various liquid plate fittings, alternative fan options and custom thermoelectric circuits to meet specific electrical or cooling needs. We also offer several compatible pump models for this chiller. FEATURE OVERVIEW: TYPICAL APPLICATIONS:

COMMON FEATURES FOR ALL SUBASSEMBLIES CONNECTIONS: Mounted 6-Terminal Connector (Cable termination optional) COMPONENTS: 80x38mm Ball Bearing Fan, High Fin Density, Anodized 6063 Al Heat Sink, Extruded Aluminum Liquid Plate, High Reliability Thermoelectric Modules, Custom Sheet-metal Anodized Al Shroud, Stainless Steel Fasteners RELIABILITY: Fans: >50K hours MTBF, Fan Perf.: 74.5 CFM, 0.57 in-H2O, 51.6 dBA, TEC’s: >100,000 hours MTBF DC INPUT NOMINAL PERFORMANCE ASSEMBLY DIMENSIONS DC INPUT NOMINAL PERFORMANCE DC INPUT NOMINAL PERFORMANCE DC INPUT NOMINAL PERFORMANCE ASSEMBLY DIMENSIONS

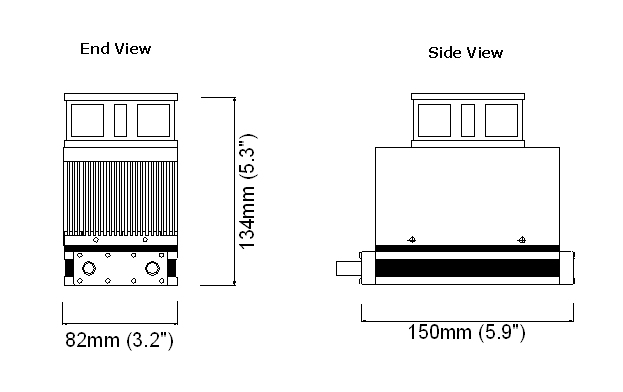

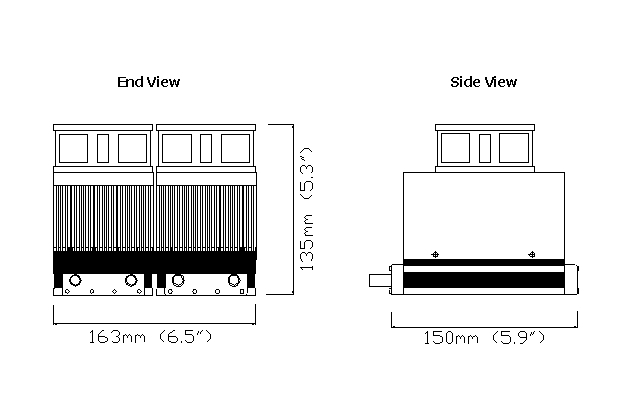

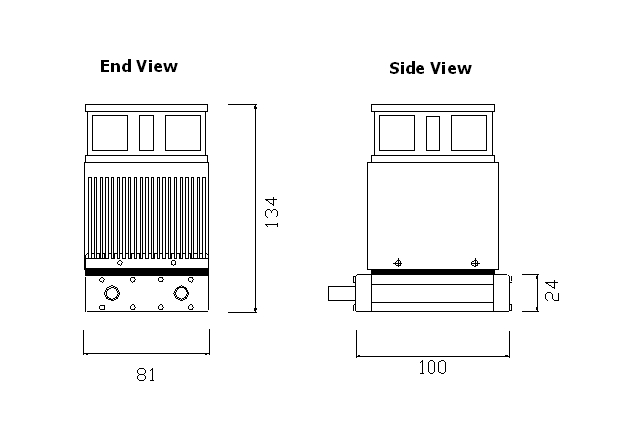

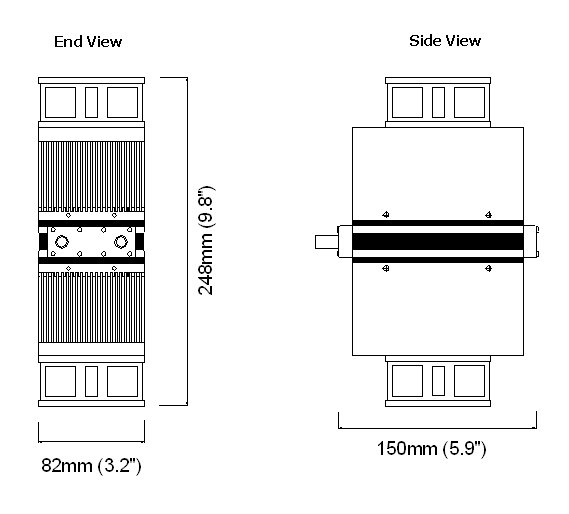

ASSEMBLY DRAWINGS P/N AL15080 Single Air-Liquid Chiller P/N AL150160 Dual Air-Liquid Chiller P/N AL15080DI Dual In-Line Air-Liquid Chiller

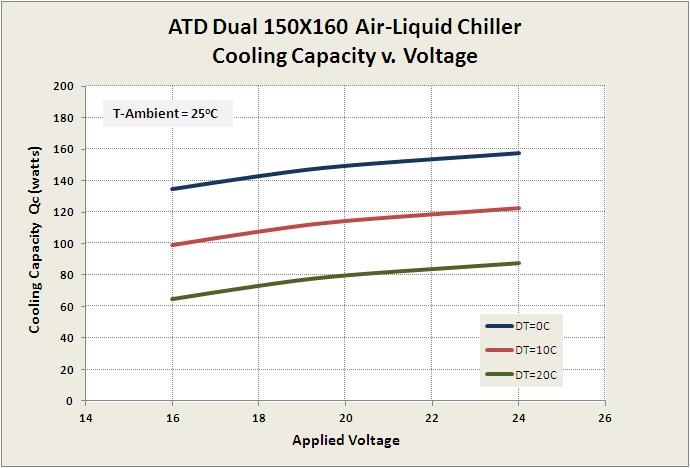

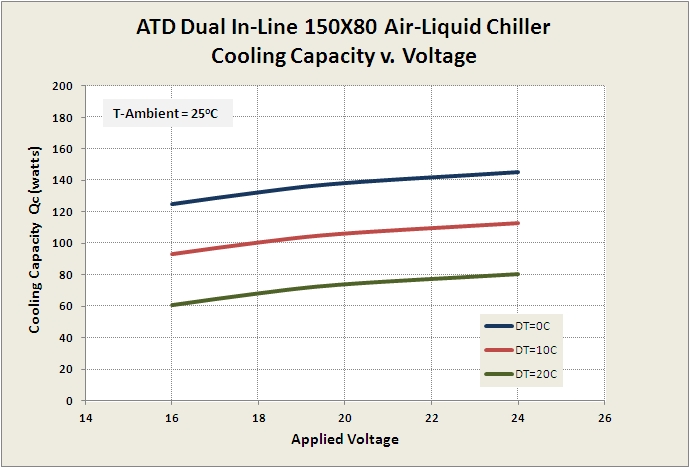

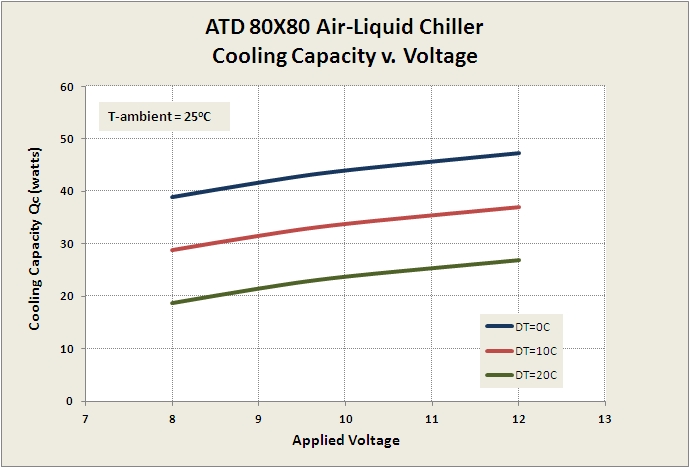

SINGLE AIR-TO-LIQUID CHILLER Description: Single chiller utilizing two TECs wired in parallel (1SX2P). Recommended operating voltage is 12 volts. Qc = cooling capacity in the liquid plate. Ta = ambient temperature in heat sink. Tc = fluid temperature. COP = coefficient of performance (Qc/Pin). Links to other performance curves for this subassembly (P/N AL15080): COP v. Voltage Curve (click to link) >> Qh v. Voltage Curve (click to link) >> Current v. Voltage Curve (click to link) >> DUAL AIR-TO-LIQUID CHILLER Description: Dual chiller, modular design utilizing two single chillers with each possessing two TECs wired in parallel (1SX2P). Recommended operating voltage is 24 volts. Qc = cooling capacity in the liquid plate. Ta = ambient temperature in heat sink. Tc = fluid temperature. COP = coefficient of performance (Qc/Pin). Links to other performance curves for this subassembly (P/N AL150160D): COP v. Voltage Curve (click to link) >> Qh v. Voltage Curve (click to link) >> Current v. Voltage Curve (click to link) >> DUAL IN-LINE AIR-TO-LIQUID CHILLER Description: Dual in-line chiller, consisting of two heat sinks and fans and a single liquid plate configured two TECs circuits wired in series (2SX1P) on each side of the liquid plate. Recommended operating voltage is 24 volts. Qc = cooling capacity in the liquid plate. Ta = ambient temperature in heat sink. Tc = fluid temperature. COP = coefficient of performance (Qc/Pin). Links to other performance curves for this subassembly (P/N AL15080DI): COP v. Voltage Curve (click to link) >> Qh v. Voltage Curve (click to link) >> Current v. Voltage Curve (click to link) >> COMPACT 80×80 AIR-TO-LIQUID CHILLER Description: Single compact chiller utilizing a single TEC designed to operate at 12VDC. Qc = cooling capacity in the liquid plate. Ta = ambient temperature in heat sink. Tc = fluid temperature. COP = coefficient of performance (Qc/Pin). Links to other performance curves for this subassembly (P/N AL8080): COP v. Voltage Curve (click to link) >> Qh v. Voltage Curve (click to link) >> Current v. Voltage Curve (click to link) >> Other performance curves at alternate temperatures available upon request.

Description

AL Chiller

TypeDimensions

(mm)Cooling Capacity

(watts)Nom. Input Power

(watts)

Single

150x82x134(H)

79

145

Dual

150x164x134(H)

158

290

Dual In-Line

150x82x248(H)

140

290

Compact

100x82x134(H)

47

74

Specs.

_______________________________________________________________

SINGLE AIR-TO-LIQUID CHILLER PRICING $209 (Qty1-10)

P/N AL15080

Vin = 12 Volts (TEC Circuit), Iin = 11-12 amps

Vin = 12 Volts (Fan), Iin = 0.7 amps

Max. Cooling Qc = 79 watts

(T ambient=25°C, DT=0C)

150mm (L) x 82mm (W) x 134mm (H)

Weight: 1.7 Kg (3.7 lbs.)_______________________________________________________________

DUAL AIR-TO-LIQUID CHILLER PRICING $417 (Qty1-10)

P/N AL150160D

Vin = 24 Volts (TEC Circuit), Iin = 11-12 amps

Vin = 24 Volts (Fan Circuit), Iin = 0.6 amps

Max. Cooling Qc = 158 watts

(T ambient=25°C, DT=0C)

ASSEMBLY DIMENSIONS

150mm (L) x 165mm (W) x 134mm (H)

Weight: 3.5 Kg (7.7 lbs.)_______________________________________________________________

DUAL IN-LINE AIR-TO-LIQUID CHILLER PRICING $379 (Qty1-10)

P/N AL15080DI

Vin = 24 Volts (TEC Circuit), Iin = 11-12 amps

Vin = 24 Volts (Fan Circuit), Iin = 0.6 amps

Max. Cooling Qc = 143 watts

(T ambient=25°C, DT=0C)

ASSEMBLY DIMENSIONS

150mm (L) x 82mm (W) x 248mm (H)

Weight: 2.8 Kg (6.2 lbs.)_______________________________________________________________

COMPACT AIR-TO-LIQUID CHILLER

P/N AL8080

Vin = 12 Volts (TEC Circuit), Iin = 5-6 amps

Vin = 12 Volts (Fan Circuit), Iin = 0.7 amps

Max. Cooling Qc = 47 watts

(T ambient=25°C, DT=0C)

100mm (L) x 82mm (W) x 134mm (H)

Weight: 1.1 Kg (2.5 lbs.)_______________________________________________________________

Drawings

P/N AL8080 Compact Air-Liquid ChillerPerformance

P/N AL15080

Please note: Cooling performance curves reflect net cooling capabilities of the chillers, exclusive of performance losses from heat gains through piping, connector or reservoir walls as well from pumps. We recommend that all chiller systems be designed carefully and well insulated on all piping, connectors, etc. Efficient pumps, well sized for the system, should also be employed to further reduce heat gain. _______________________________________________________________

P/N AL150160D_______________________________________________________________

P/N AL15080DI_______________________________________________________________

P/N AL8080Order / Enquiry