Our 80mm liquid plate is a custom design with high internal surface area and good fluid flow properties. It has more than double the wetted surface area of a typical 4-pass, embedded copper tube plate. The mounting surfaces are 150mm(L) x 80mm(W) with a compatible mounting pattern to our 130x80mm heat sink and cold plate. Standard fluid connections are 8mm (5/16″) push-to-connect or 3/8″ barb fittings, other fitting types are optional.

Our 80mm liquid plate is a custom design with high internal surface area and good fluid flow properties. It has more than double the wetted surface area of a typical 4-pass, embedded copper tube plate. The mounting surfaces are 150mm(L) x 80mm(W) with a compatible mounting pattern to our 130x80mm heat sink and cold plate. Standard fluid connections are 8mm (5/16″) push-to-connect or 3/8″ barb fittings, other fitting types are optional.

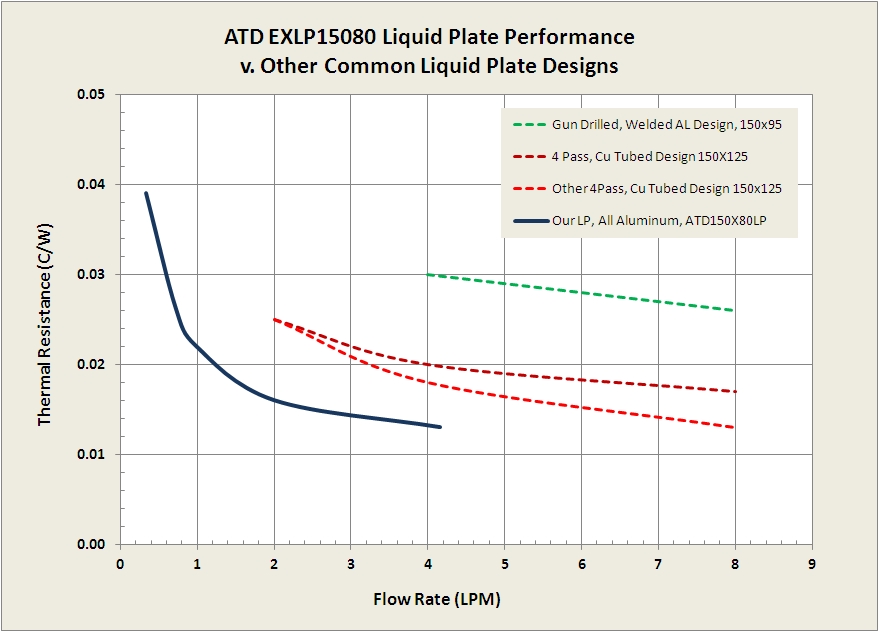

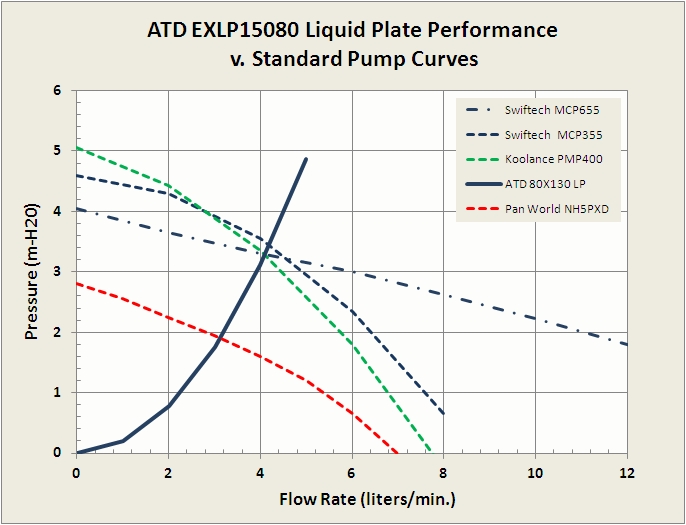

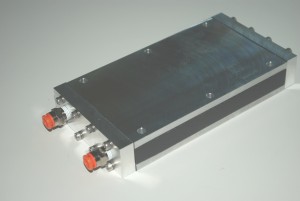

150X80 LIQUID PLATE PRICING $59 (Qty1-10) Liquid cold plates circulate fluids (generally water or a water/glycol mixture) internally to actively move heat from (or to) the surface of the liquid plate. The high thermal film coefficient and good heat capacity of liquids enable very low thermal resistance levels to be achieved. Liquid plates employed in TEC-based assemblies usually include either: 1) plates with embedded or attached copper tubes, 2) plates with gun drilled passages or 3) plates with more complex machined internal features. The narrower passages and high internal surface area of the machined-type plates generally yields the best thermal performance but generally at much higher pricing. We have developed an extruded liquid plate design with performance approaching machined-type plates with high internal surface area but is offered at much more competitive pricing. Our 80mm aluminum liquid plate (LP) is a thick walled extruded design, milled smooth and flat for low resistance interfacing and good heat spreading. It will easily accommodate multiple TEC’s or other heat generating sources, on either side. Our LP has attractive fluid flow properties yielding a thermal resistance of 0.016 C/W at 2 LPM. The good performance at low flows eases the pump requirement which generally translates to lower cost, a more compact design and less added heat by the pump in to the process stream (i.e., therefore more net cooling power). The recommended flow range for the plate is 1-4 LPM (0.25-1.0 GPM) (rated pressure drop of 3.2 m wc (0.32 bar) at 4.1 LPM). The end plates on this design have 1/8″ NPT penetrations and are mechanically fastened to the centerbody which allows removal for inspection and periodic internal cleaning to remove any performance degrading build up, e.g., oxides, deposited solids etc. Cooling capacity can be readily expanded by linking multiple liquid plates in either series or parallel.

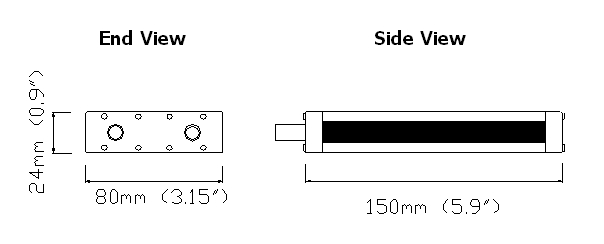

PERFORMANCE: ______________________________________________________________ SPECIFICATIONS: 150mm (L) x 80mm (W) x 24mm (H) ______________________________________________________________ PART DRAWING ______________________________________________________________ PERFORMANCE CURVE AND COMPARISON

Description

P/N ELP15080Technical

Thermal Resistance: 0.016 oC/watt at a flow of 2.0 LPM (0.53 GPM) of water. See curve below for a range of flow rates.

Weight: 0.75 Kg (1.6 lbs.)

Eight internal channels configured eight in series

Removable endplates for inspection and servicing (if required)

Inlet/Outlet: 1/8” NPT Press Fit Coupling (female)

Mounting: six 4mm clearance holes, three per side,

Material of construction: type 6063 aluminum

Finish: bright, milled top and bottom surfacesOrder / Enquiry