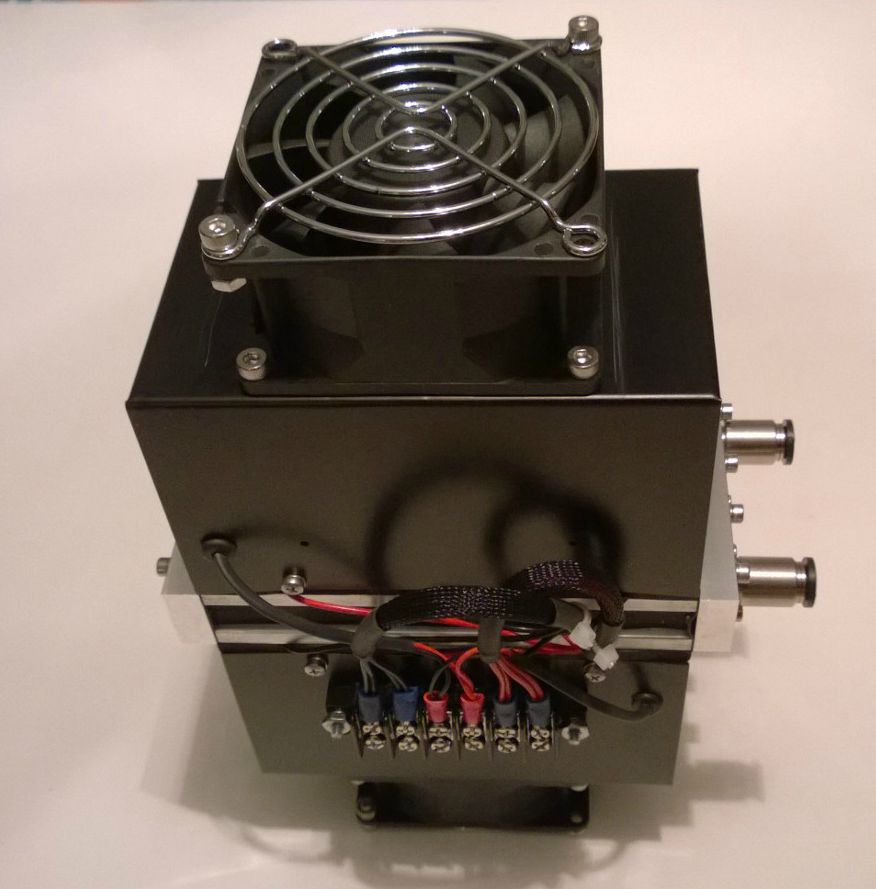

Our DUAL In-Line, Air-to-Liquid Chiller (Model # AL15080DI) provides 143 watts of liquid cooling at an ambient temperature of 25oC (re-circulating water temperature 25oC). This design is very compact with a footprint of just 150mm x 82mm (6” x 3.2”) and height of 248mm (9.8”). This chiller is especially suited for internal placement in equipment, such as analytical instrumentation or medical lasers, but can be effective for any application requiring chilling, heating or precise temperature control of a fluid. Other suggested applications might include medical therapy, industrial processing equipment, aquarium temperature control, electronics and optical cooling.

Instead of Freon-based compressors, our chiller uses compact solid-state Peltier (thermoelectric) technology at the core to actively and precisely pump heat. The design is rugged and corrosion resistant with carefully designed components to provide a long operating life. Power for the chiller is safe, low voltage DC which can be either applied fixed or varied to accurately maintain a temperature set point. Standard operating voltage for this design is 24 VDC (or 0-24 VDC), but the circuit wiring is flexible so the chiller can alternatively be wired to operate at fixed levels of 12 or 48 VDC.

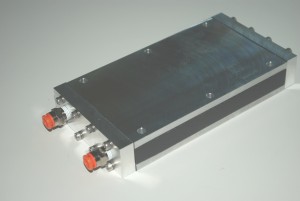

The liquid plate in this chiller is a custom, multi-channel design with internal passage dimensions chosen to provide good thermal performance without undue flow restriction. Consequently, the liquid plate can operate effectively at moderate flow rates (1-4 lpm) allowing a range of pump types to employed. Standard fittings for the liquid plate include 8mm (5/16”) push to connect SS fittings or 3/8” barb fittings. One end of the liquid plate is machined with 1/8″ NPT holes to accept a range of fitting types.

High fin density heat sinks, positioned on either side of the liquid plate, are single piece, anodized aluminum extrusions similar in fin density and performance to bonded-fin types. Elimination of the adhesive bonded fin joints, however, offers enhanced performance and reliability advantages. The DC axial fans are the only moving parts in this design and are high reliability, ball bearing type from a reputable manufacturer. The heat sink/fan combination is an especially important consideration for Peltier chillers since it strongly influences the maximum cooling capacity and overall efficiency achievable. The resultant thermal resistance of this compact heat sink, fan and shroud combination is an attractive 0.08 C/W.

Pricing (quantity 1-10) for the DUAL In-Line chiller is $379. Significant discounts are available for higher quantities. Please contact us to discuss your specific chiller needs.